Produtos > PUNCHING SOLUTIONS > Tools Sharpening Service

Tools Sharpening Service

Tools sharpening

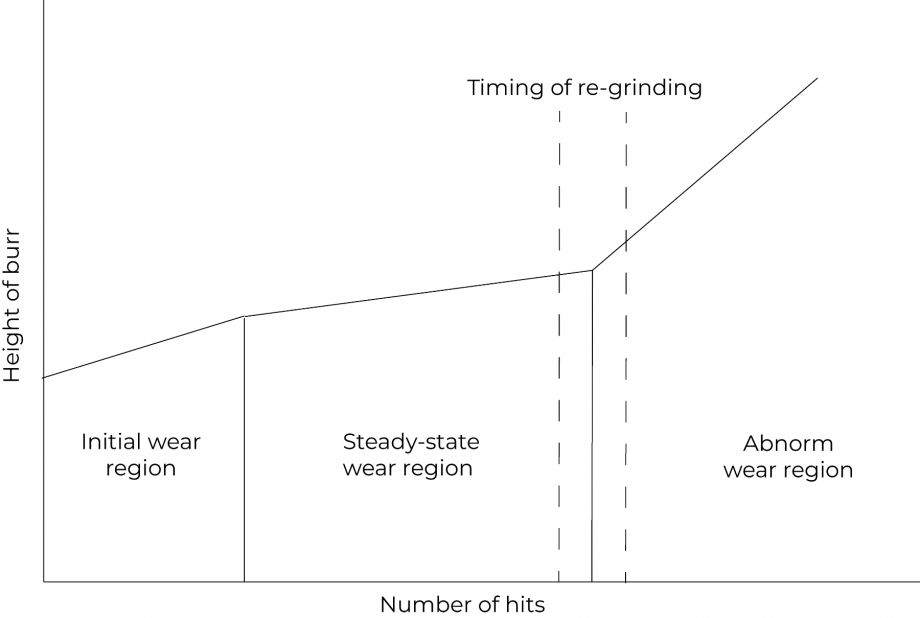

Most of our customers believe that the less they regrind tools, the most will run in the machine the longer they will last and are strongly convinced to save money. But due to our experience this is not correct, and in order to help you to understand better this very important concept, we kindly ask you to have a look at the following charts and explanation.

Considering product quality and machine life, punch and die should be sharpened frequently. More tool dull, more burrs and rollover increase. Tool dull quickly when processing resistant material, such as stainless steel.

But we found that for being able to get the higher tool performance, you have to regrind once the corner radius on punch tip is around 0,15mm.

More than DOUBLE tool life when regularly and frequently sharpened!

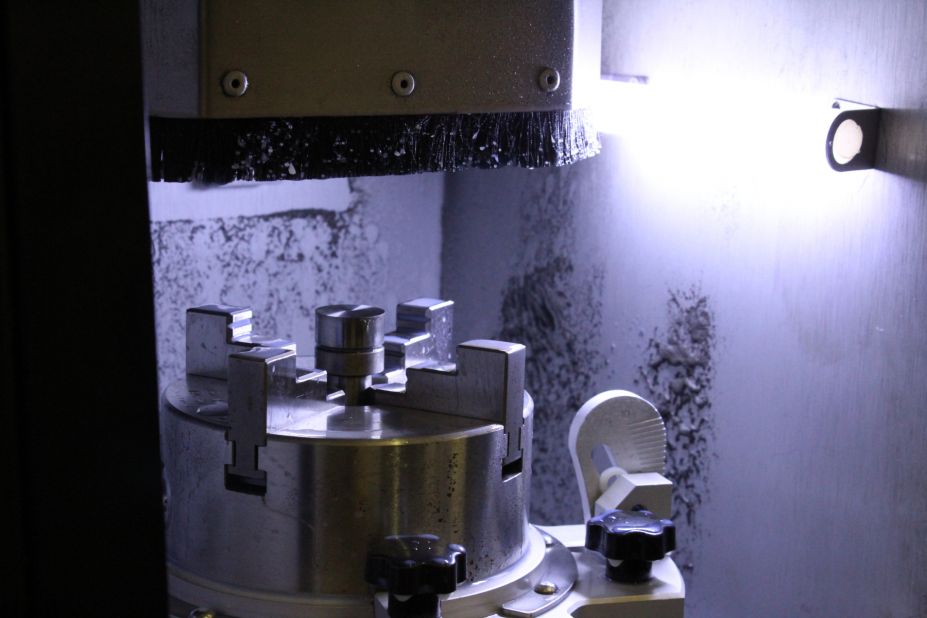

Thanks to our machinery we are able to provide a quality service for R1 and R2 type:

R1 type:

- A-B stations and Multitool max Ø 12.7

- C-D-E Stations

- A–B stations and multitool max Ø 2.7 whisper and rooftop

- C–D–E stations whisper and rooftop

- Sharpening type double valley shear

- Sharpening type four way shear

- Sharpening from flat to whisper A–B stations and Multitool max Ø 12.7

- Sharpening from flat to whisper C-D-E stations

- Sharpening rooftop punches with flat part

R2 TYPE:

- Up to Ø31

- Over Ø31

- Up to Ø31whisper and rooftop

- Over Ø31 whisper and rooftop

- Sharpening type double valley shear

- Sharpening type four way shear

- Sharpening from flat to whisper size 1

- Sharpening from flat to whisper size 2